Highlights

-

- Robust mechanical structure suitable for high speed

- Axis speeds with an average of 95 m/d

- Profiling length 4175 mm- Machinable profile section size 300 x 300 mm

- Number of clamps 6 pieces

- Spindle motor 8.5 kW 24,000 rpm

- The number of magazine sets is 8- Ø 200 mm saw

- Mitsubishi CNC control unit

- Vices positioned by the X-axis

- Automatic tool recovery in case of power failure

|

Description

|

|||||||

| Machine Features | X Axis | Motor power | 3,5 | kW | |||

| X Axis | Axis Speed | 135 | m/min | ||||

| X Axis | Maximum Machining Length | 4175 | mm | ||||

| Y Axis | Motor power | 0,75 | kW | ||||

| Y Axis | Axis Speed | 110 | m/min | ||||

| Y Axis | Max Machining Width | 300 | mm | ||||

| Z Axis | Motor power | 0,75 | kW | ||||

| Z Axis | Axis Speed | 45 | m/min | ||||

| Z Axis | Max Machining Height | 300 | mm | ||||

| Tool | Motor power | 8,5 | kW | ||||

| Tool | Max Rotation Speed | 24000 | rpm | ||||

| Magazine | Tool Number | 8 | Piece | ||||

| Magazine | Maximum Saw Diameter | 200 | mm | ||||

| Clamp | Number of Clamps | 6 | Piece | ||||

| Feed | Voltage | 400 | V | ||||

| Technicial Specifications | Air | Pressure | 6-8 | bar | |||

| Air | Total Air Consumption | 161 | l/min | ||||

| Feed | Power | 19 | kW | ||||

| Weight | Net | 5670 | kg | ||||

| Weight | Gross | 6305 | kg | ||||

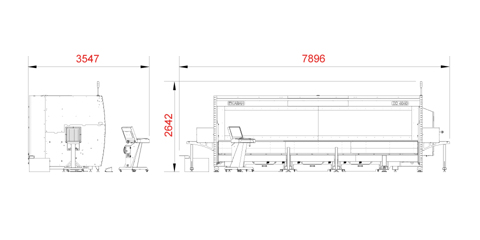

| Machine Dimensions | Length | 7896 | mm | ||||

| Machine Dimensions | Width | 3547 | mm | ||||

| Machine Dimensions | Height | 2642 | mm | ||||

Design

- Mechanical structure that can process aluminum and steel

profiles at high speed and high quality

- Stress relieved cast and welded parts to ensure consistent high speed accuracy

- Axis speeds with an average of 95 m/min.

- Ability to perform milling, notching, drilling, threading, countersinking, cutting, etc.

- Profile machining length 4175 mm

- Machinable profile section size 300 x 300 mm

- Automatic lubrication system

- Coolant spray system

- Stress relieved cast and welded parts to ensure consistent high speed accuracy

- Axis speeds with an average of 95 m/min.

- Ability to perform milling, notching, drilling, threading, countersinking, cutting, etc.

- Profile machining length 4175 mm

- Machinable profile section size 300 x 300 mm

- Automatic lubrication system

- Coolant spray system

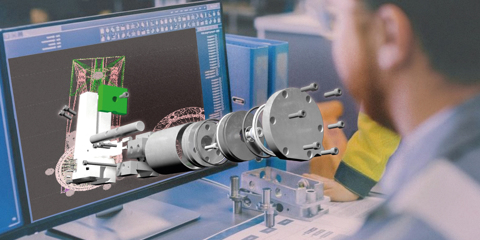

Control Panel

- Versatile adjustable, ergonomic kiosk

- 19'' screen

- User-friendly Kaban interface with Windows-based, easily adjustable parametric structure

- Compatibility with .NCX extension software

- High performance 3 axis Mitsubishi CNC control unit

- Optical communication and command increment

- Communication via Ethernet

- Working with G-Code

- Data transfer via USB and COM Port

- 19'' screen

- User-friendly Kaban interface with Windows-based, easily adjustable parametric structure

- Compatibility with .NCX extension software

- High performance 3 axis Mitsubishi CNC control unit

- Optical communication and command increment

- Communication via Ethernet

- Working with G-Code

- Data transfer via USB and COM Port

Spindle

- 8.5 kW / 24,000 rpm

- HSK F63 tool holder

- Encoder

- Temperature control

- Liquid cooling

- Tool cooling

- HSK F63 tool holder

- Encoder

- Temperature control

- Liquid cooling

- Tool cooling

Profile Supports

- Automatic profile support system on both sides

- Suitable for working with long profiles

- Suitable for working with long profiles

Vices

- Narrow clamps designed to be protected against external

influences

- 6 standard clamps

- Clamps positioned by the X-axis

- Ease of profile sliding on the clamp surface with roller system

- Three different clamping forces according to the profile thanks to the pressure regulator

- 6 standard clamps

- Clamps positioned by the X-axis

- Ease of profile sliding on the clamp surface with roller system

- Three different clamping forces according to the profile thanks to the pressure regulator

Security

- Ability to continue from where it left off in case of power

failure with the UPS system

- Auto-recovery function that sends the spindle to the safe zone

- Working safety with cover and safety barriers

- Auto-recovery function that sends the spindle to the safe zone

- Working safety with cover and safety barriers

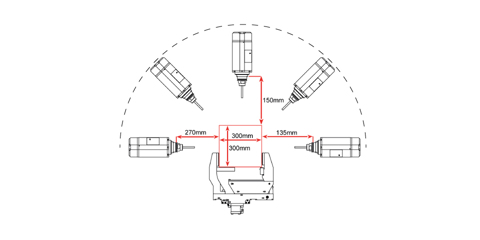

Angle Tool Holder

- 90° tool for processing the bottom surface of the profile.

- T tool for machining the left and right surfaces of the profile.

- T tool for machining the left and right surfaces of the profile.